Precision is crucial in stonework and construction. Achieving the perfect cut or finish demands the right tools. These tools, known as Stone CNC Tools, are the workhorses behind the scenes, allowing fabricators to shape stones accurately.

While lacking the glamour of the finished structures and sculptures they help create, Stone CNC tools are the bedrock upon which these masterpieces are built. They are the precise instruments that chisel, carve, and sculpt stone into its intended form. Stone CNC tools are the unseen hands that turn stone into architectural wonders, detailed sculptures, and functional pieces that stand the test of time.

But Stone CNC Tools come in various forms, and today, we are here to discuss the most common types of such tooling through this blog. Let’s get started!

Primary Applications Of Stone CNC Tools

Stone CNC Tools are the backbone of the stonework industry, offering precision, efficiency, and versatility in various applications.

- Architectural Stonework: These tools shape stone for building facades, countertops, and architectural details.

- Monument and Sculpture Creation: They’re used to carve detailed inscriptions, patterns, and artistic designs on stone surfaces.

- Countertop and Vanity Production: Ideal for crafting elegant countertops, ensuring precision-cut sink openings and polished edges.

- Stone Flooring: Used to cut and shape stone tiles for visually striking and seamless stone flooring.

- Functional Stonework: Essential for creating anchor holes, faucet openings, and stone fireplace surrounds in construction.

- Artistic Stone Carvings: Artists rely on these tools to sculpt detailed sculptures, patterns, and unique designs in stone.

- Restorations and Repairs: Vital for preserving and restoring historical stone structures and monuments.

- Custom Stonework: Offers tailored solutions, allowing craftsmen to meet unique design requirements across various applications. These tools empower artisans to combine precision and artistry in stonework.

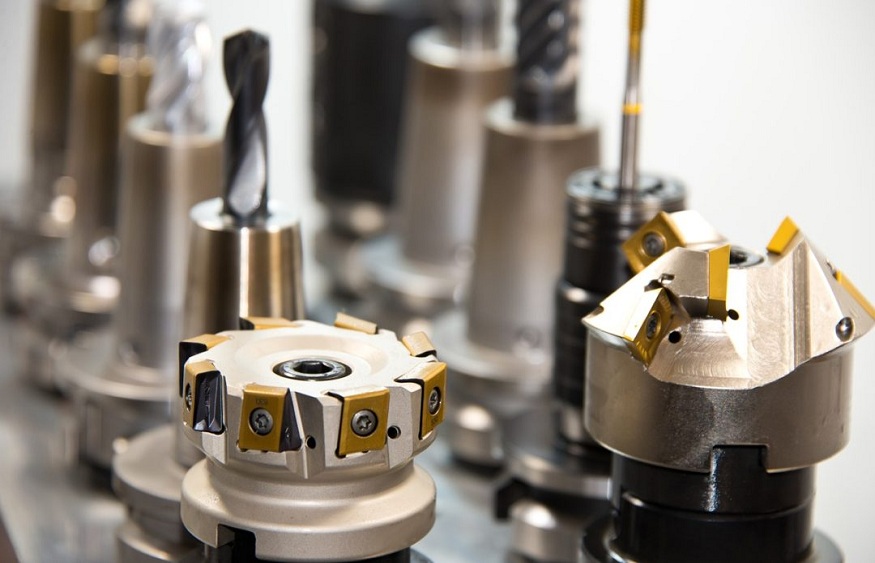

Common Types Of Stone CNC Tools

Stone CNC tools have applications in various industries, including construction, interior design, and monument making. Here are some common types of stone CNC tools:

Diamond Router Bits

These specialized tools feature diamond-tipped edges that precisely profile and shape stone edges. They come in various profiles, allowing artisans to create decorative borders on stone surfaces, such as countertops and staircases. Diamond router bits are the finishing touch that enhances the aesthetic appeal of stonework, giving it a polished and refined look.

Diamond Core Bits

Diamond core bits are the tool of choice for creating holes in stone, whether for sink cutouts, faucet holes, or anchor holes in construction. They come in wet and dry variations to suit different applications, making them versatile and essential for drilling precise holes in stone surfaces.

Diamond Grinding Wheels

Diamond grinding wheels are instrumental in achieving smooth and polished stone surfaces. They are designed to level uneven surfaces, remove imperfections, and create a glossy finish. Their role in enhancing stone’s visual and textural quality cannot be understated.

Diamond Saw Blades

Diamond saw blades are stone-cutting workhorses. They make precise cuts in stone materials for straight lines, curves, or intricate designs. Stone CNC machines rely on these versatile tools for shaping stone surfaces for many applications.

Diamond Engraving Bits

Diamond engraving bits come into play when intricate detailing and delicate design work are required on stone surfaces. They are adept at creating finely detailed inscriptions, patterns, or decorative designs on stone, offering a means to personalize and add artistic elements to stonework.

Polishing Pads

The specialty of polishing pads is achieving a smooth and reflective finish on stone surfaces. Available in various grits, they allow craftsmen to hone and polish stone to perfection. The result is a gleaming and polished surface that accentuates the natural beauty of the stone.

Finger Bits

Finger bits are indispensable for intricate carving and detailed work in confined spaces. These specialized tools are valuable for working around sink cutouts and creating finely detailed designs on stone surfaces, ensuring precision in tight areas.

Drum Wheels

Drum wheels are critical for shaping and smoothing curved and rounded edges on stone surfaces. They play a significant role in creating elegant and polished edges, such as those found on countertops and vanity tops, enhancing the visual appeal and functionality of the stonework.

CNC Tool Holders

CNC machines rely on secure tool holders to accommodate Stone CNC Tools. These holders come in various sizes and types, ensuring a snug fit for different tool shanks. They are pivotal in maintaining precision and control over CNC machines during stonework, enabling accurate and intricate machining.

CNC Vacuum Pods

Many CNC machines in the stone industry require Vacuum cups or pods to hold the stone slabs to the table. They create a suction, so that the slab is not moved or pushed during the cutting and polishing process. High quality vacuum pods, such as BVC green pods, are important for the finished product to come out perfect.

Shop for Stone CNC Tools at Tait Sales & Consulting

Regarding sourcing top-quality Stone CNC Tools for your stonework projects, there’s a trusted destination that shines—Tait Sales & Consulting. As you’ve explored the versatility and significance of these tools in various applications, consider diving into the world of precision craftsmanship with the unsung heroes behind remarkable stonework.

With a commitment to reliability, performance, and versatility, Tait Sales & Consulting provides tools from industry-trusted brands, assuring you of the highest quality. Our experienced team is not only about delivering equipment; we offer expert guidance to help you select the right tools tailored to your specific requirements.

So, explore their array of Stone CNC Tools with confidence, knowing you’re equipping yourself with the tools that transform stone into enduring masterpieces. Your stonework projects deserve nothing less than the best, and Tait Sales & Consulting is here to make that a reality.

+ There are no comments

Add yours